Best Spring Washer Manufacturer in Africa - Cameroon

- Home

- Best Spring Washer Manufacturer in Cameroon

We at Lakshmi Steels under brand of GEAR( redefining Quality) are proudly introducing ourselves as growing spring lock washer manufacturing company since 2004, which is being established to serve the various type of industries with wide range of variety. We have well established fully equipped plant to manufacture superior quality washers and catering to industries around. Which is achieving the success under the best management team Being an ISO 9001:2015 certified company; we are following all the quality procedure to control the quality aspects. We always inspire to upgrade quality control team to make the perfect product. We control all the steps of production from the raw material upto the final dispatch with proper traceability of production.

Gear: Delivering Quality and Excellence

LEADING SPRING WASHER MANUFACTURE IN CAMEROON (AFRICA)

LAKSHMI STEELS has carved its niche in the industry as one of the recognized spring washer manufacturers in Cameroon. Since the establishment, we have a sole aim of manufacturing the product range that helps our clients get their hands on the best they deserve. Our products are designed for meeting the diverse needs of different processes and get tested on several quality parameters before sending to the customers. We at Lakshmi Steels under brand of GEAR (redefining Quality) are proudly introducing ourselves as growing spring lock washer manufacturing company since 2004, which is being established to serve the various type of industries with wide range of variety. We have well established fully equipped plant to manufacture superior quality washers and catering to industries around.

What We Offer

Split Lock Washers

Spring Washers

Flat Spring Washer

Spring Lock Washer

Pre Thread Spring Washer

Stainless Steel Spring Washer

Conical Spring Lock

Special Krunling Washer

Washer

Product Details

Information about products

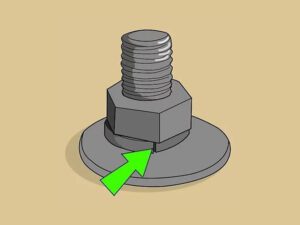

Spring washers are normally made out of spring steel and are hardened to HV 430 to 530 and are used along with almost every externally threaded fastener. Due to their Spring action, they give a locking effect to the tightened fastener, when fastened with Spring washer.

Flat and square sections are the most common used types of spring washers. Square section spring washers are normally used for fasteners with cylindrical heads and flat section for all other type of heads. Square section spring washers are lighter, and thereby cheaper than the ones with rectangular section.

These washers are normally available in auto black (black) finish. Other finishes like White/Yellow/Blue Zinc coating (with hydrogen de-embrittlement), cadmium plated, nickel-plated, bright chromium plated and phosphated are also available.

Specification

Materials: Low Carbon Steel, Spring Steel (EN42), Aloy Steel, Stainless Steel, Phosphor-Bronze, Silicon-Bronze, Nickel-Copper-Aluminum and any other material to the customers requirments.

Size: M2 to M99, 1/8” to 1-3/4"

Finish: plain, oiled, auto black, hot-dip galvanized, electroplated (with de-embrittlement)

Standards

DIN 127B (Flat Section), DIN 7980 (Square section), ASME B18.21.1 (Helical Spring-lock washers – regular, heavy, extra-duty & high-collar), JIS B 1251 (Regular & Heavy duty), IS 3063, IS 6735, BSS 1802, BS 4464, DIN 6905, DIN 128, NFE 25-(515-517).

Non Specification

Any Raw Material Specification - Any Non Standard Part - Any Unique Drawing - Any Different Specifications - Any Surface Finish - Any Packing Requirement - Any Specific Testing

Tests

Chemical composition, Hardness, Decarburization, Washer cross-section, Coiling, twist test, free height, toughness, appearance, compression test.

Our Blogs

Windows Loader for Windows ✓ Activate Windows 7 OOBE Easily

Windows loader for windows activates Windows 7 and older OS ✓ bypass official activation ➤ fast, reliable tool ★ activate during OOBE with ease.

adult telegram group links ✓ Join 80+ Best Adult Groups Now!

Adult Telegram group links help you discover and join the best 18+ groups. ✓ Access curated links and connect with like-minded individuals today!

The Production

A+ Production with quality product

Gear is a one of leading manufacture of superior quality washers. We

manufacture around 400,000,000 Washers annually among Which

many of these are of standard parts. But the proportion of unique

dimensions is increasing year after year.